One of the key challenges for batteries is their ability to cope with fluctuating temperatures. Extreme heat or cold can have a significant impact on battery performance and lifespan. Understanding how batteries respond to temperature variations is essential in ensuring their optimal functioning and longevity.

Additionally, batteries face other stresses in their daily usage. Factors such as vibration, mechanical shocks, and exposure to moisture or chemicals can all affect battery performance and reliability. It is crucial to assess and evaluate these stresses to accurately specify the battery’s performance and ensure it meets the requirements of your products.

Common safety risks during battery testing include overheating, crack in the separating membrane and over/undercharging.

The risks are depending on how and what product is being tested. The majority of tests require safety level 3 with more complex testing requiring up to level 6.

Testing batteries in different temperatures is essential to understand and evaluate their performance and behavior under varying environmental conditions. Here are a few reasons why temperature testing is crucial:

Performance Optimization: Batteries exhibit different characteristics at different temperatures. Testing helps identify the optimal temperature range for their operation, ensuring maximum efficiency and performance. It enables manufacturers to fine-tune their designs and control systems to optimize battery performance in real-world scenarios.

Safety Assessment: Extreme temperatures can impact the safety of batteries. Testing helps identify potential risks and vulnerabilities associated with temperature fluctuations. By evaluating battery behavior under different temperature conditions, manufacturers can implement safety measures and design safeguards to prevent overheating, thermal runaway, or other hazardous events.

Battery Lifespan: Temperature has a significant impact on battery lifespan. Extreme heat or cold can accelerate degradation and reduce the overall life expectancy of a battery. Testing in various temperature ranges helps estimate the expected lifespan and allows manufacturers to develop strategies to prolong battery life through thermal management techniques and optimal operating conditions.

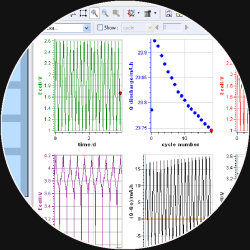

Capacity and Power Delivery: Batteries may experience reduced capacity and power output at extreme temperatures. Testing provides insights into the effect of temperature on a battery’s ability to deliver consistent power and maintain its rated capacity. This information is crucial for designing systems that can handle temperature-related performance fluctuations effectively.

Reliability and Durability: Batteries are subject to various stresses during their lifetime, including temperature fluctuations. Testing helps assess the reliability and durability of batteries under different temperature conditions. It allows manufacturers to identify potential weaknesses or vulnerabilities and make design improvements to enhance overall battery performance and longevity.

Environmental Adaptability: Batteries are used in diverse applications and environments, ranging from automotive to aerospace and portable electronics. Testing in different temperatures ensures that batteries can perform reliably across various climates and operating conditions, guaranteeing their suitability for specific applications and markets.

A controlled environmental chamber, also known as a temperature chamber or climate chamber, is a specialized enclosure used to create and maintain precise temperature, humidity, and sometimes other environmental conditions for testing or storage purposes. It is designed to simulate and replicate specific environmental conditions that a product, material, or specimen may encounter during its intended use or in various applications.

Stability test with constant climate, temperature and humidity cycling and extreme climate testing with high and sub-zero temperature.

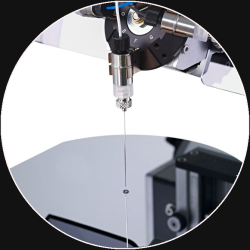

We offer battery cyclers, potentiostat and accessories for battery testing and electrochemistry to be integrated with our climatic chambers.

See more of our battery test instruments HERE.